Factory Hot Sell Electric Air Pressure Pneumatic Automatic Dual-Position Heat Transfer Printing Press Machine

Price range: 310,00 $ through 1.258,00 $

Description

|

Serial No.

|

Product name

|

Printing Size

|

Box size (CM)

|

Weight (KG)

|

|

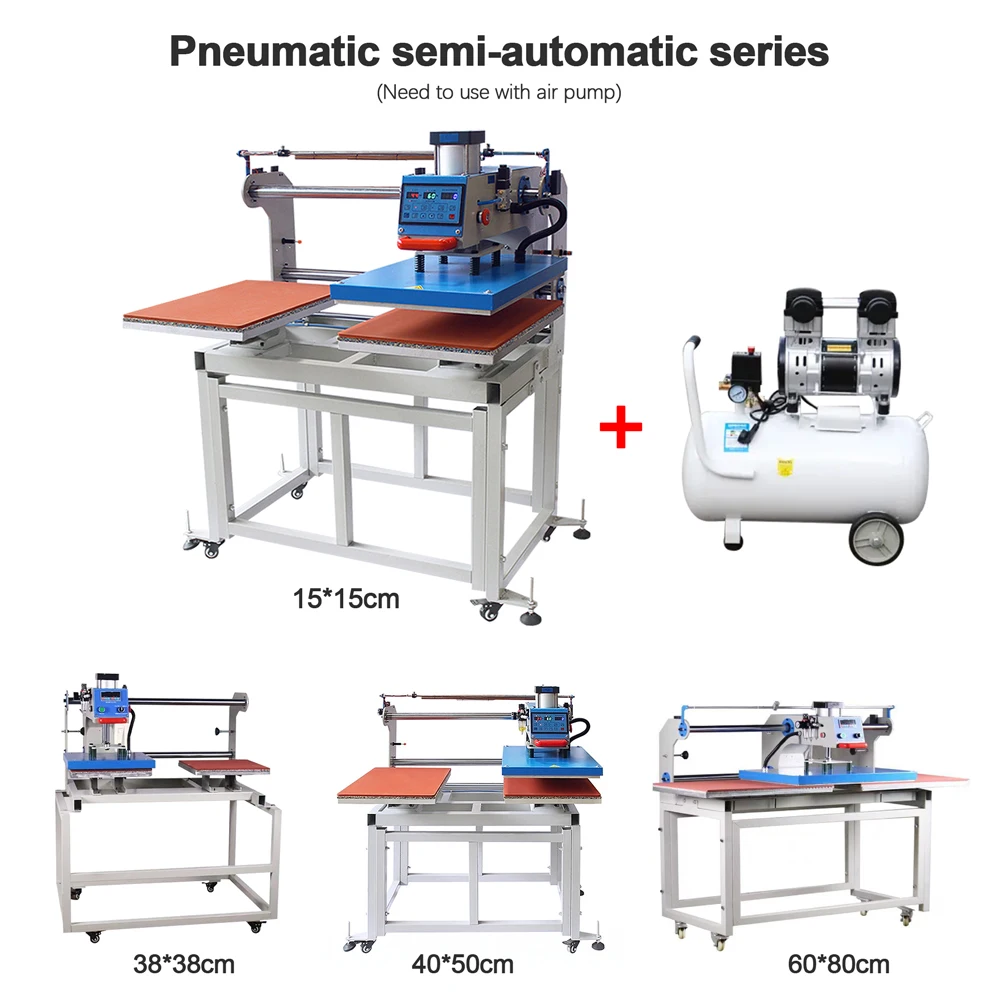

1

|

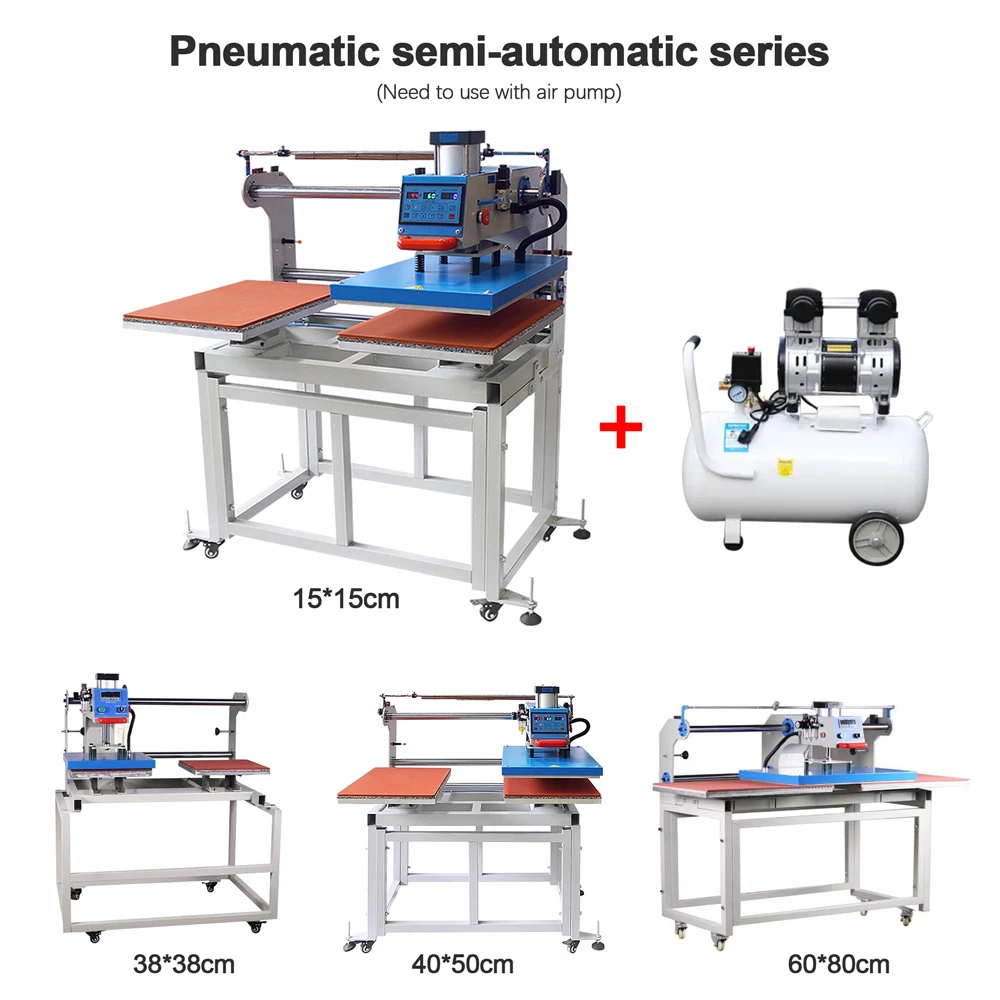

Pneumatic Semi-automatic

|

Printing Size: 15*15cm

|

76*60*70

|

61

|

|

2

|

Pneumatic Semi-automatic

|

Printing Size: 38*38cm

|

120*95*85

|

145

|

|

3

|

Pneumatic Semi-automatic

|

Printing Size: 40*50cm

|

125*95*85

|

153

|

|

4

|

Pneumatic Semi-automatic

|

Printing Size: 60*80cm

|

170*105*890

|

215

|

|

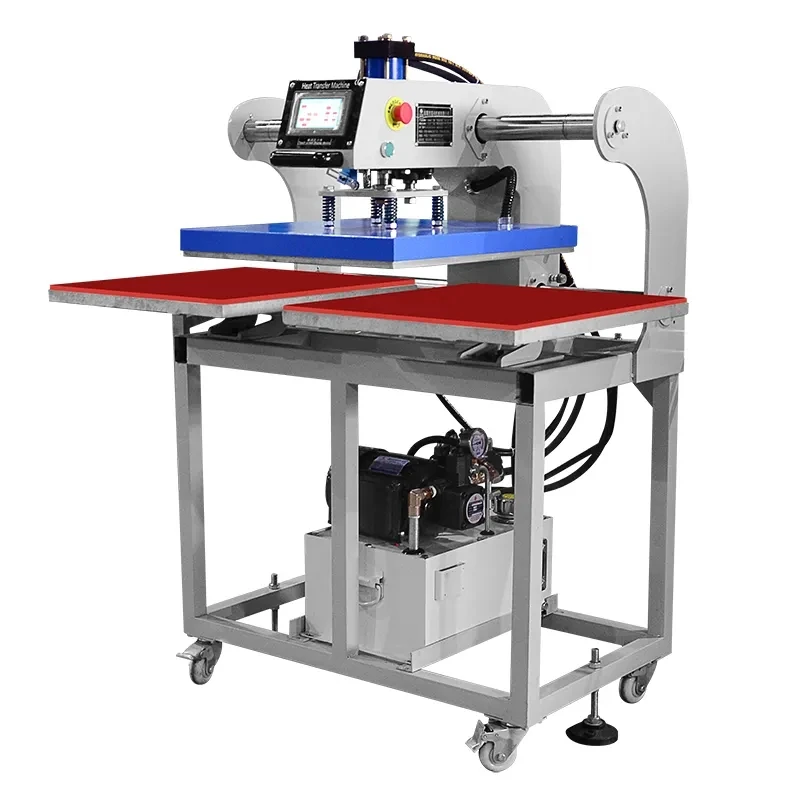

5

|

Hydraulic Semi-automatic

|

Printing Size: 40*50cm

|

125*85*85

|

270

|

|

6

|

Hydraulic Semi-automatic

|

Printing Size: 40*60cm

|

125*95*85

|

280

|

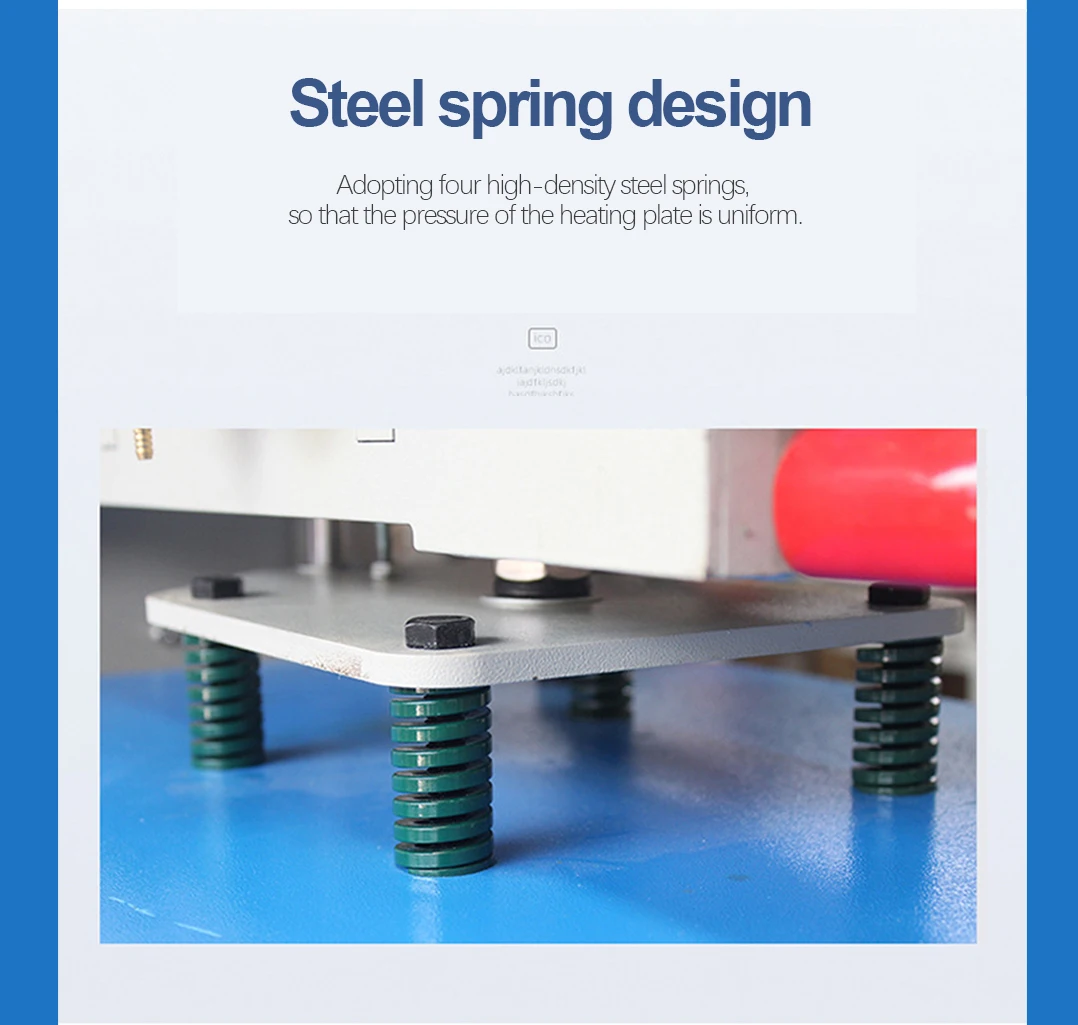

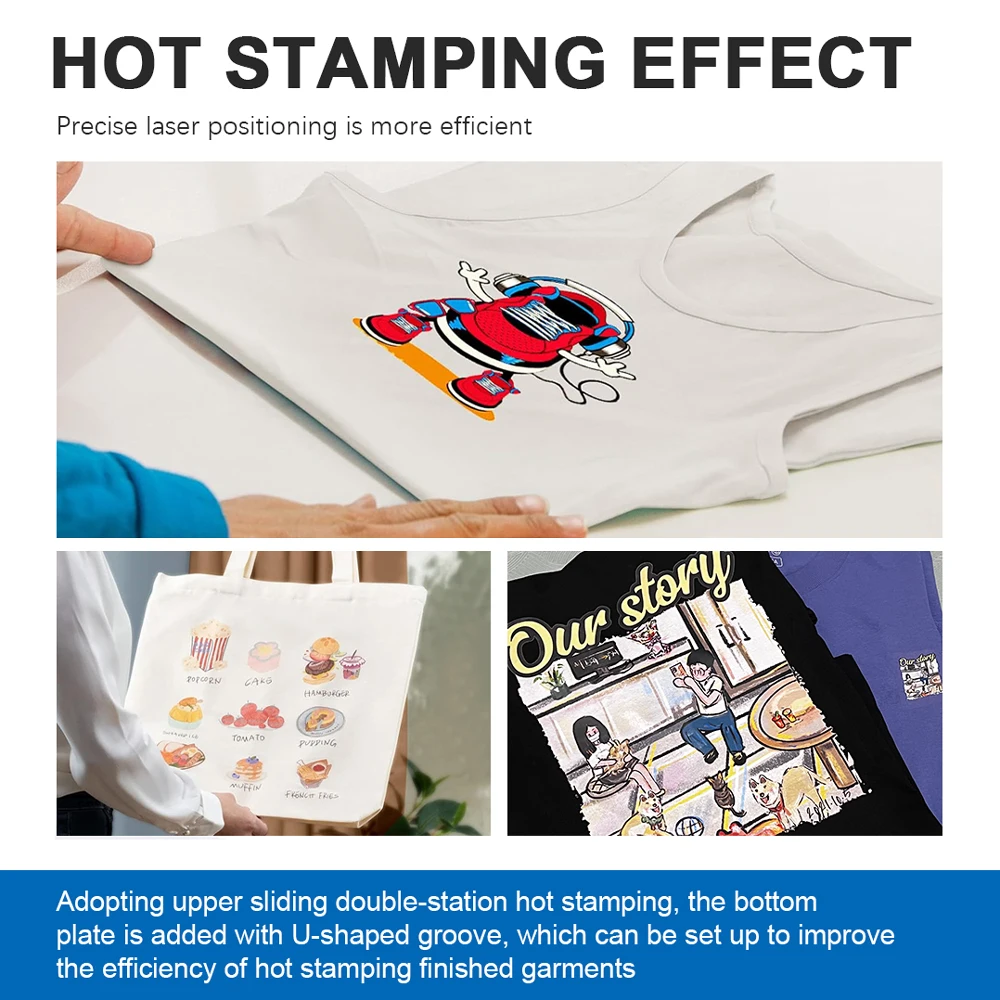

Pneumatic/Hydraulic Semi-automatic 2-Station Heat Press Machine

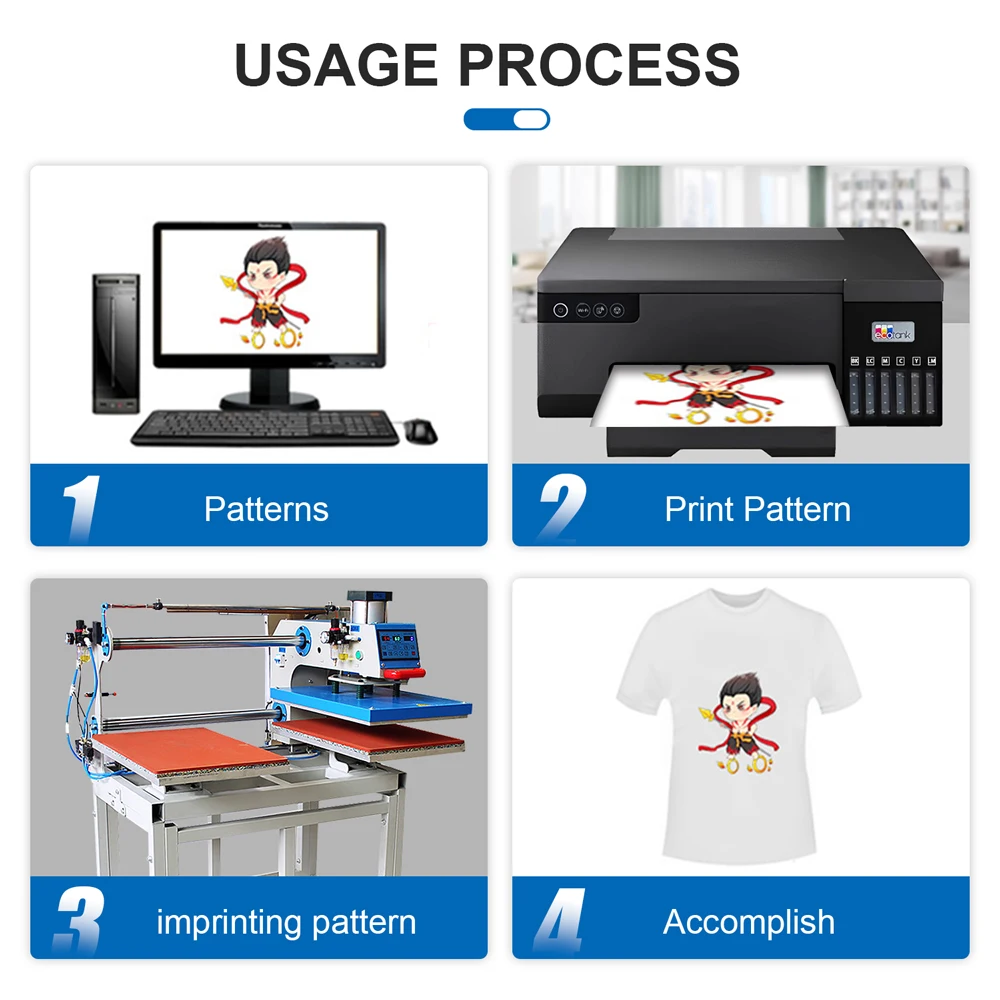

1. Material Bonding:

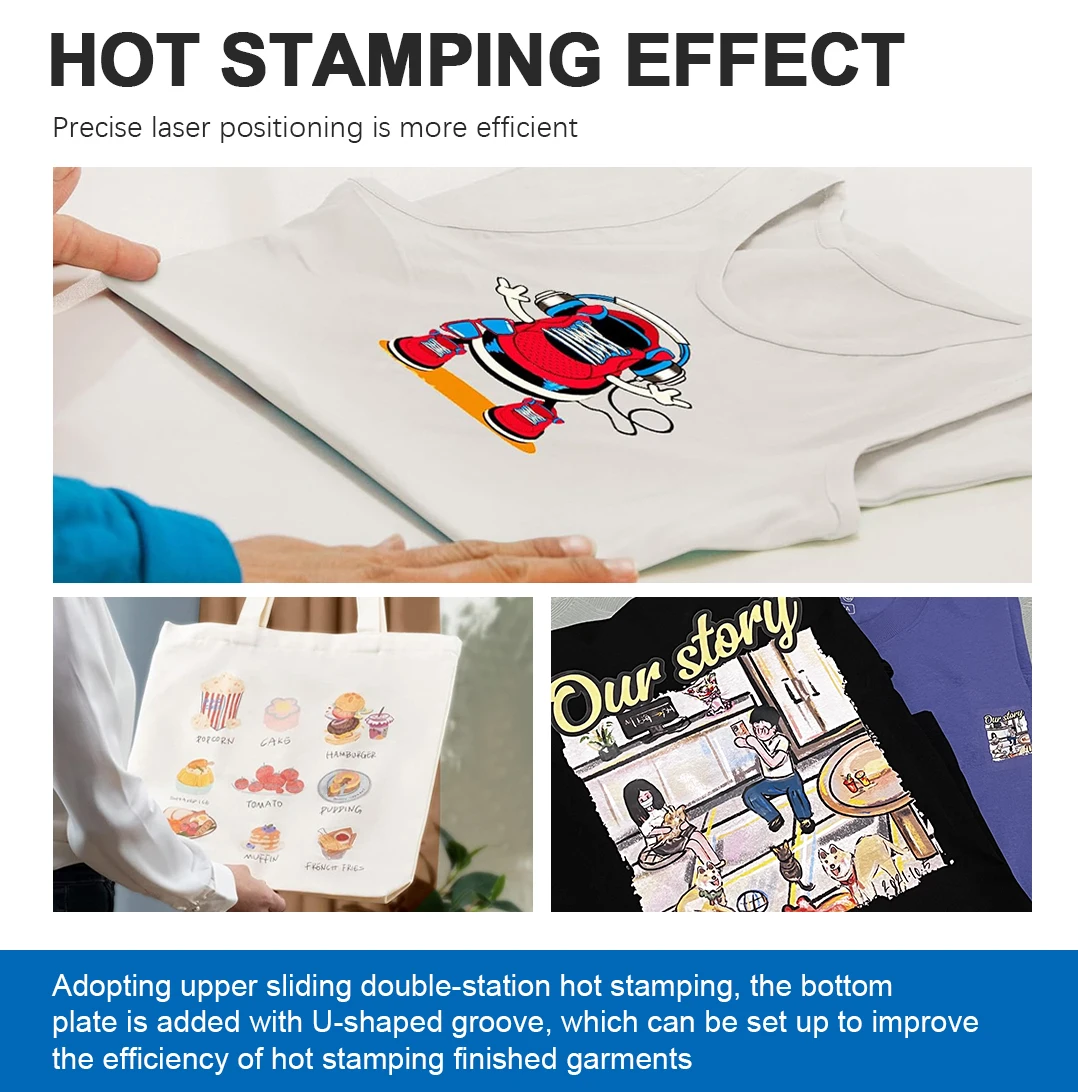

Pneumatic heat press machines are primarily used to bond materials together through the application of heat and pressure. They are widely utilized in industries such as printing, textiles, and manufacturing.

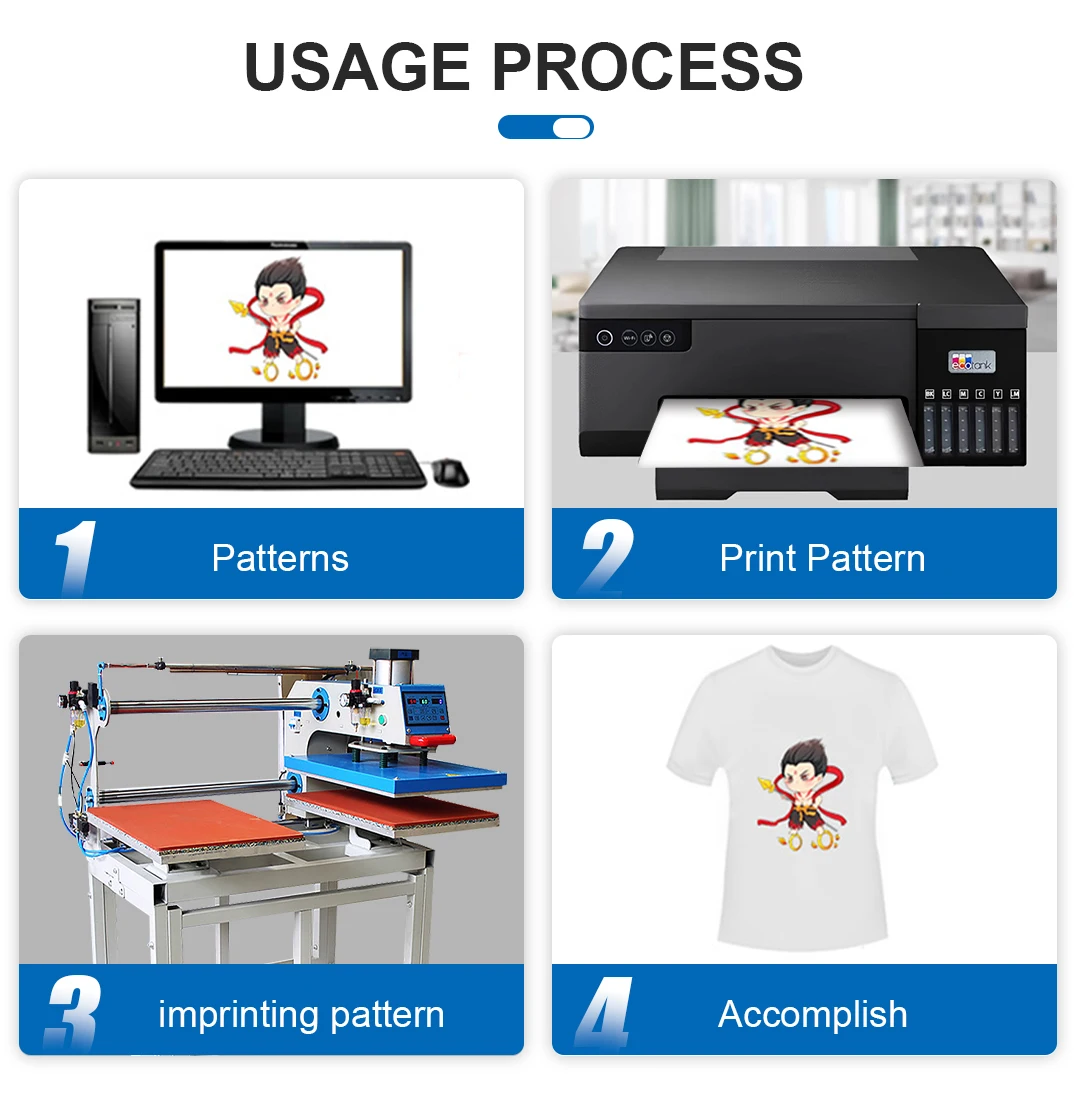

2. Printing Industry:

In the printing industry, automatic heat press machines are commonly used to imprint logos, designs, or textonto items such as t-shirts, bags, hats, and other materials.

3. Manufacturing:

Beyond textiles, heat press machines can also be used in manufacturing processes where bonding layers of material with heat and pressure is necessary.

Recommend Products

Product descriptions

About us

Pneumatic & Hydraulic ,Fully automatic and semi-automatic difference

Pneumatic dual-station and hydraulic dual-station hot stamping machines differ primarily in their power source and operating mechanisms. Pneumatic machines use compressed air to drive the press, which allows for quick, precise movements and is generally quieter and more energy-efficient. They are also easier to maintain due to fewer moving parts.

Both types offer dual stations for increased productivity, but the choice between pneumatic and hydraulic often depends on the specific requirements of the application, such as the type of materials being processed and the desired pressure and speed.

Hydraulic machines, on the other hand, use fluid pressure to operate the press, providing greater force and stability for heavy-duty applications. They are known for their durability and high pressure capabilities but can be louder and require more maintenance due to the hydraulic system.

Both types offer dual stations for increased productivity, but the choice between pneumatic and hydraulic often depends on the specific requirements of the application, such as the type of materials being processed and the desired pressure and speed.

Fully automatic and semi-automatic hot stamping machines differ in the level of human intervention required during operation. Fully automatic machines are designed to perform the entire hot stamping process without manual assistance, from loading the materials to unloading the finished product. They are equipped with advanced controls and sensors that automate all steps, including temperature control, pressure application, and timing. This automation leads to increased efficiency, consistency, and production speed, making them ideal for high-volume production lines.

Semi-automatic machines, in contrast, require some manual input at various stages of the process. Operators typically need to load and unload materials, and may also need to adjust settings or perform quality checks. Semi-automatic machines offer more flexibility in terms of job setup and can be more cost-effective, but they are generally slower and less consistent than fully automatic models. They are often chosen for lower volume production or when the flexibility to handle a variety of jobs is more important than high-speed, automated production.

Reviews

There are no reviews yet.